-

OVERVIEW

Biomass / coal boilers / heating application / waste incinerator :

For dust particulate matter (PM) emission control in high temperature exhaust stream which are produced from the solid fuel combustion. Existing dedusters such as cyclones and multi-cyclone are inefficient to meet the current stringent emission limits (≤ 50 mg/Nm3) which is imposed by the regulatory commission.

Electrostatic Precipitators (ESPs) uses DC high voltage for charging dust particle & are very high efficient emission control dedusters for a given range of dust resistivity with respect to particular temperature but on other side it requires maintenance with high operating cost their by increases the total cost of ownership

Bagfilters as a physical filtration process with very high efficient emission control dedusters but on other side requires regular high maintenance & compressor air consumption for cleaning the filter media and with the regular new filter replacement due to this high shutdown means loss in production.

Client's needs a very robust and highly efficient emission control device at reasonable price, which can operate at any temperature range with low maintenance & operating costs for continuous year of operation.

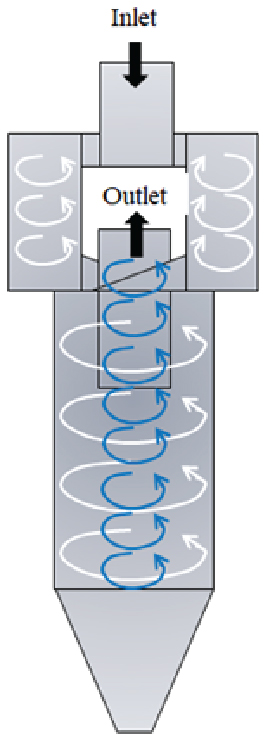

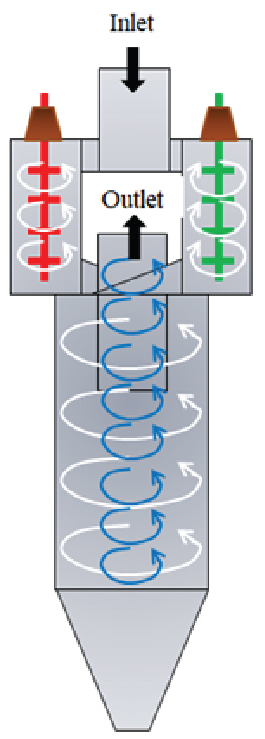

PRODUCT SCHEMATIC

Particlones

Particlones-ES

APPLICATION

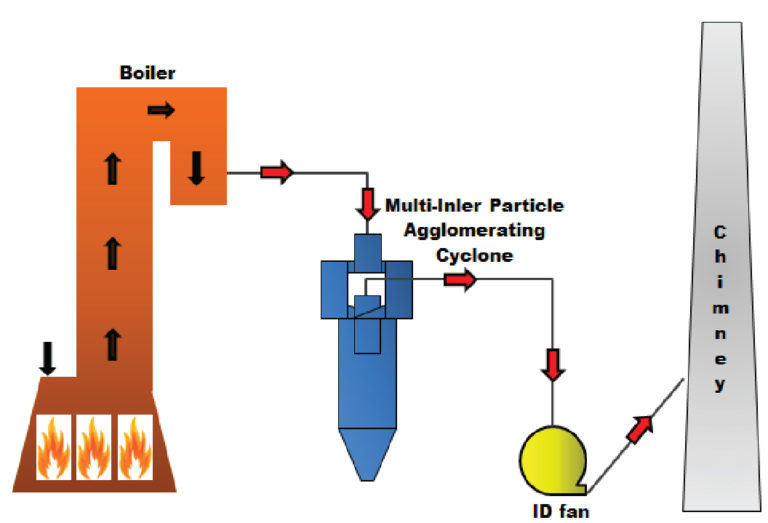

As a Emission Control

- Coal & Biomass Boilers

- Steel & Ferrous alloys

- Gasification

- Calcination processes

- Glass & Ceramic process

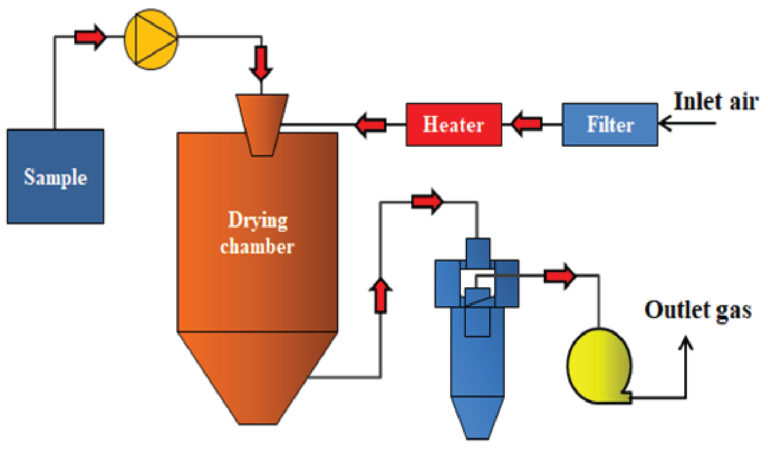

- Drying processes

- Clinker cooler air de-dusting

- Other separation processes

As a Product/Powder Recovery

- Pharmaceutical

- Chemicals

- Fertilizers

- Milling & drying processes

- Catalysts

- Food ingredients

- Mineral processing

Multi-Inlet Particle Agglomerating Cyclone as emission control device

Particulate matter emission control is a typical problem in every industry that operate boiler/ Furnace / waste incinerators for energy or steam production, kilns and dryers for material manufacturing.

Complying with emission limits, avoiding the escape of particles to downstream processes or purifying ambient air are the main motivations for clients to reduce particulate matter emissions.

Multi-Inlet Particle Agglomerating Cyclone as a process product recovery

Powderhandling with a very fine particle is typical problem in chemical & Pharmaceutical industries and faces high product losses. Improving the efficiency of powder recovery is main motivation for the clients to minimizing their product losses.

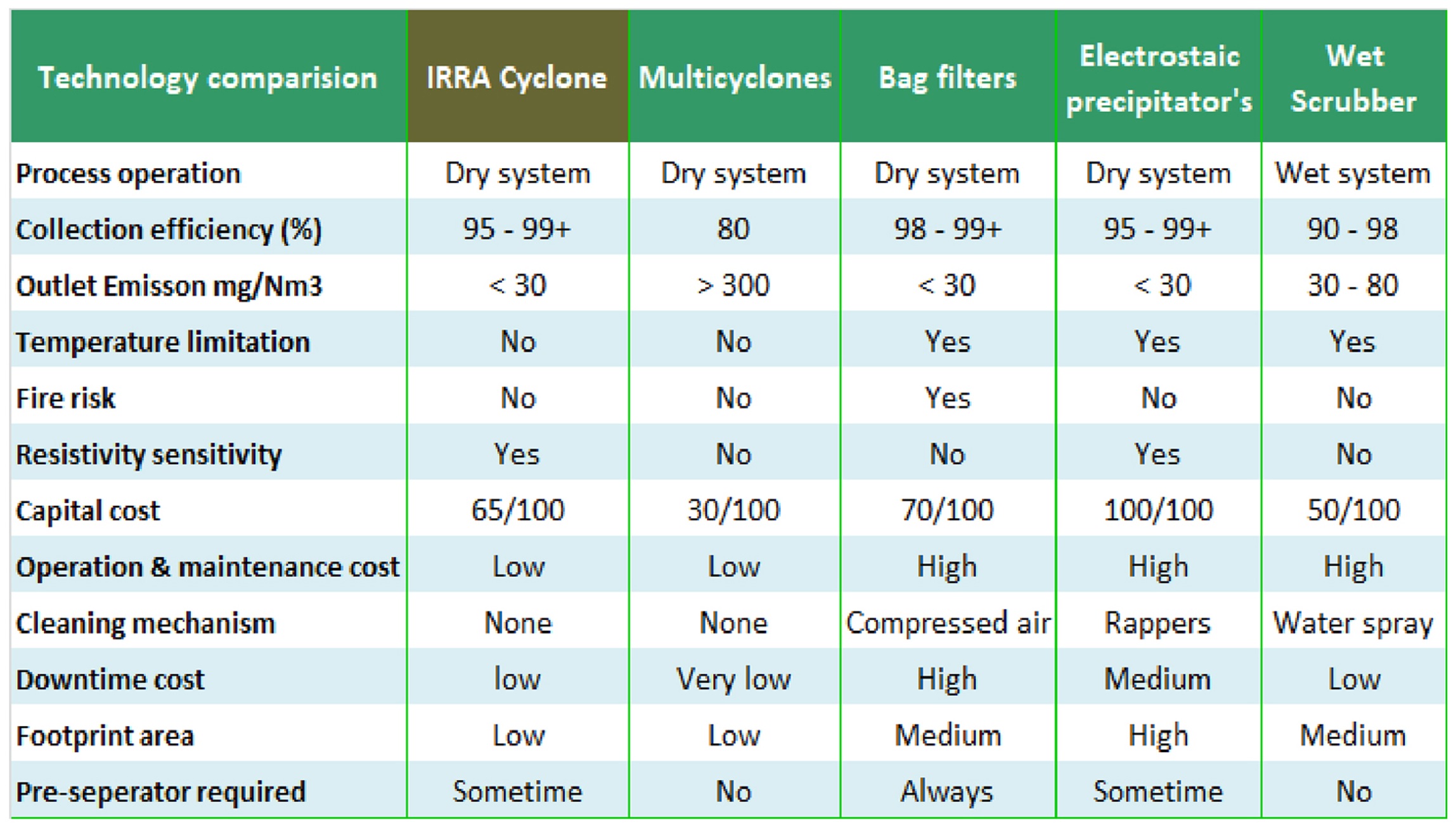

Technologies comparison

Comparitive study of existing particle seperation technologies with proposed “IRRA Cyclone System”

FEATURES

-

Very low emissions: [30-50mg]/Nm3 is achievable for many combustion sources

-

Customized designs (single or parallel arrangement)

-

Low pressure drop: < 100 mmWC

-

No temperature restrictions

-

Robust construction with no moving parts

-

Near zero maintenance and downtime costs

-

Very low operating costs

-

Low investment cost

KNOW MORE

Get in touch with us for demo and more information.